by Inez Kim October 1, 2024

Building Management Systems (BMS) are crucial in automating and controlling various functions in modern buildings, including HVAC, lighting, security, and energy management. A well-designed BMS ensures efficient building operations, reduced energy consumption, and enhanced occupant comfort. However, one of the critical components that underpins a BMS’s functionality is its wiring requirements and infrastructure. Proper wiring ensures seamless communication between the various devices and sensors connected to the system.

Understanding the wiring requirements for BMS is essential because a poorly wired system can result in operational inefficiencies, data loss, and even system failures. BMS wiring must accommodate diverse communication protocols, electrical loads, and environmental factors, all while adhering to industry standards and regulations. In addition to functional aspects, safety is a critical consideration, as improper wiring can pose risks such as electrical hazards and system malfunctions.

This article will explore the essential wiring considerations for BMS, including types of cables used, wiring topologies, protocols, and proper planning to ensure long-term performance and reliability in building management system wiring.

In This Article

ToggleWhat Is Building Management Systems (BMS)?

A Building Management System (BMS) is a centralized platform used to control, monitor, and optimize various building operations, improving energy efficiency, operational performance, and occupant safety and comfort. Key systems typically managed by a BMS include:

HVAC (heating, ventilation, and air conditioning): A BMS regulates temperature, humidity, and air quality by automating HVAC settings based on occupancy, time, and weather. This improves comfort and reduces energy waste.

Lighting control: BMS optimizes lighting by adjusting levels according to occupancy and daylight. Automated lighting control reduces energy consumption and extends the life of lighting systems.

Power distribution: The system monitors electricity flow, ensuring efficient use and preventing overloads. It can prioritize essential systems during peak loads to avoid unnecessary energy waste.

Security and access control: BMS manages access to different areas, integrates with CCTV and alarm systems, and ensures real-time monitoring, enhancing building security.

Fire alarm and detection systems: BMS integrates with fire detection systems to monitor smoke detectors and emergency exits, triggering alarms and unlocking exits during emergencies.

Water management systems: BMS monitors water usage, detects leaks, and automatically shuts off water to prevent flooding, reducing wastage and operational costs.

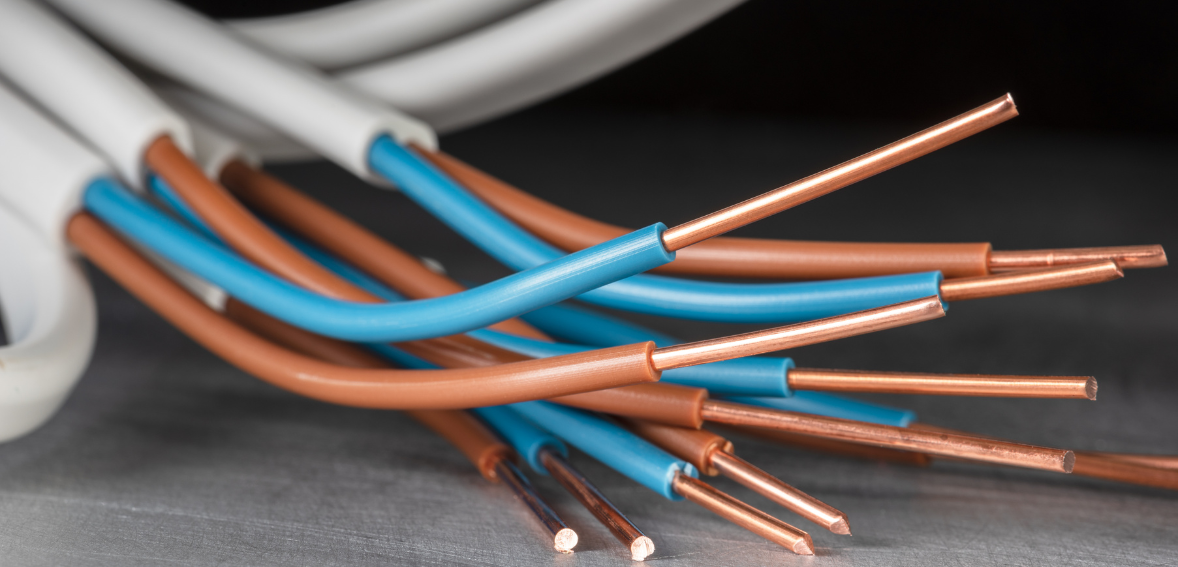

Types of Wires Used in BMS

In building management system wiring, selecting the right types of wires is critical for ensuring smooth operations, communication, and safety. BMS wiring must support power distribution, control signals, and communication protocols between various subsystems. Below is an overview of the common wire types used in BMS installations:

Power Cables

Power cables are responsible for delivering electricity to the various devices and systems controlled by the BMS, such as HVAC systems, lighting, and security equipment. These cables must be capable of handling the electrical load required by the connected equipment while maintaining safety and efficiency. Power cables used in BMS installations are typically designed to handle high voltages and currents, ensuring reliable operation of the systems they serve.

Control Cables

Control cables transmit low-voltage signals between sensors, controllers, and actuators in a BMS. These cables are used to regulate functions such as temperature adjustments, lighting controls, and security alarms.

Twisted pair cables: Twisted pair cables consist of pairs of wires twisted together to minimize electromagnetic interference (EMI) from external sources. This makes them ideal for transmitting low-voltage control signals in environments with high electrical noise, ensuring accurate data transmission. Twisted pair cables are commonly used for connecting sensors, actuators, and control panels in BMS installations.

Shielded cables: Shielded cables have a conductive layer (shield) that encases the internal wires to further protect against EMI. These cables are typically used in environments with heavy electrical interference or where data integrity is crucial, such as in control systems for sensitive HVAC equipment or security systems. Shielded cables help ensure that signals are transmitted accurately and without disruption.

Communication Cables

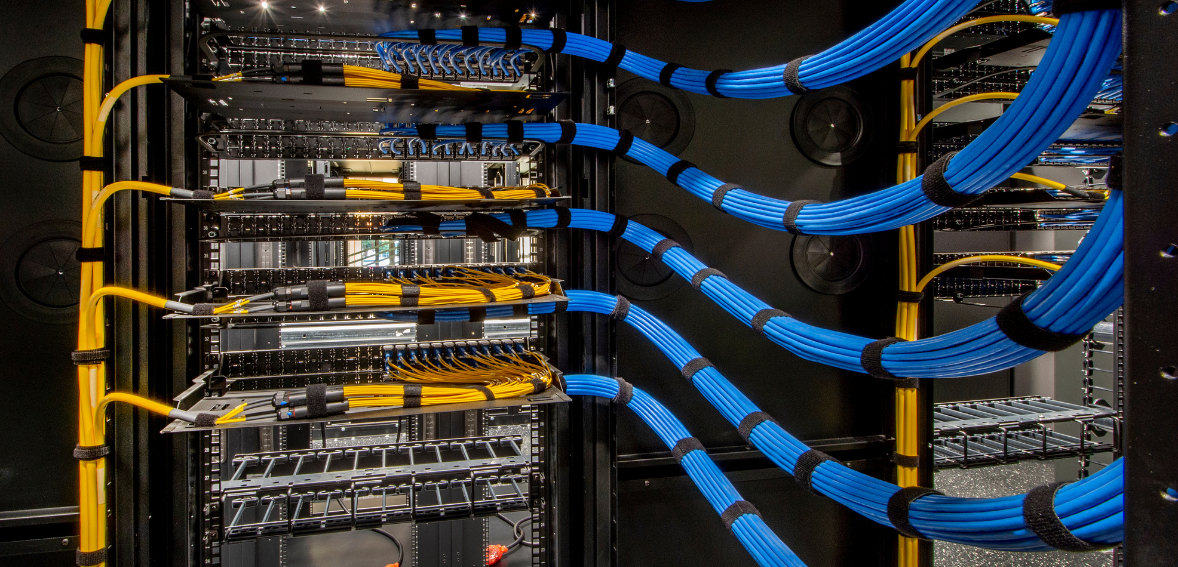

Communication cables are essential for connecting various subsystems in a BMS, allowing them to communicate and share data. The choice of communication cable depends on factors such as bandwidth requirements, distance, and data speed.

Ethernet cables: Ethernet cables are widely used in BMS to connect devices such as controllers, sensors, and user interfaces to the central management system. These cables allow for high-speed data transmission over short to medium distances. Ethernet cables support the integration of IP-based systems in a BMS, enabling centralized monitoring and control.

Fiber optic cables: Fiber optic cables are used for high-speed data transmission over long distances, making them ideal for large buildings or campuses where BMS components are spread out. Fiber optic cables offer superior bandwidth and resistance to interference, ensuring fast and reliable communication between systems. These cables are often used for connecting critical subsystems like security, fire alarms, and HVAC systems to the central BMS.

Fire Alarm Cables

Fire alarm cables play a critical role in ensuring that fire detection systems function reliably. These cables must adhere to strict safety standards to withstand the harsh conditions that may arise during a fire.

Plenum-rated cables: Plenum-rated cables are designed for use in spaces such as air ducts and ceilings, where air circulation occurs. These cables are made of fire-resistant materials that emit low smoke and toxic fumes when exposed to high temperatures. They are often used in fire alarm systems to ensure that the wiring doesn’t contribute to the spread of fire or release harmful gases in case of an emergency.

Circuit integrity (CI) cables: Circuit Integrity (CI) cables are engineered to continue functioning during a fire, even when exposed to high temperatures. These cables are essential for maintaining communication and operation of fire alarms, emergency lighting, and other critical systems during a fire. By preserving the integrity of the system, CI cables ensure that occupants have time to evacuate and that emergency response teams receive accurate alerts.

Wiring Layout Design for Building Management Systems (BMS)

The wiring layout design for a building management system wiring is crucial for ensuring optimal functionality, performance, and reliability. A well-structured layout facilitates seamless communication, system integration, and easier maintenance. Key considerations include centralized vs. decentralized systems, zoning, and wiring pathways.

Centralized vs. Decentralized Systems

When designing a BMS wiring layout, property managers and engineers must choose between centralized and decentralized system architectures, each with distinct advantages.

Centralized systems: In centralized BMS, all control functions are managed from a central location, such as a control room. Wiring routes back to a single control panel, simplifying monitoring and maintenance. However, this requires extensive wiring, increasing installation costs and the potential for communication bottlenecks.

Decentralized systems: Decentralized BMS distribute control across local zones. Each area manages specific systems like HVAC or lighting. This reduces the need for long cable runs, lowers installation costs, and enhances system flexibility. Local failures are less likely to affect the entire system, making it more resilient.

Zoning and Segmentation

Zoning groups different building areas or systems for efficient management. Dividing a building into zones minimizes cable lengths, boosts performance, and simplifies troubleshooting. This segmentation makes maintenance easier by isolating problems to specific areas, reducing system downtime.

Wiring Pathways

Proper organization of wiring pathways is crucial to maintain system efficiency, reduce interference, and ensure safety. The two primary methods of managing cables are cable trays and conduits, and the separation of power and signal wires.

Cable trays and conduits: Cable trays provide open routing for easy maintenance, while conduits offer enclosed protection from damage. Both ensure organized wiring.

Separation of power and signal wires: This prevents electromagnetic interference (EMI), protecting the integrity of signals and reducing operational issues.

Safety Standards and Compliance in BMS Wiring

Ensuring safety and compliance in building management system wiring is vital for protecting both the building and its occupants. BMS installations must meet a range of electrical, fire safety, and local regulatory standards. Proper adherence not only ensures system safety but also prevents legal issues and fines. Key safety standards and compliance considerations include:

National electrical code (NEC): The National Electrical Code (NEC), developed by the National Fire Protection Association (NFPA), provides guidelines for safe electrical installations in the U.S. The NEC covers important aspects such as wire sizing, cable routing, grounding, and protective equipment. Compliance with the NEC is mandatory for all electrical systems in the U.S., ensuring safe operation, minimizing fire risks, and safeguarding building occupants.

International electrotechnical commission (IEC) standards: Outside the U.S., International Electrotechnical Commission (IEC) standards are widely used. The IEC develops global standards for electrical systems, including BMS wiring. Following IEC standards ensures that BMS installations meet international safety, performance, and interoperability requirements, improving system reliability and safety.

Fire safety standards: BMS wiring must comply with fire safety standards to prevent fire risks. Plenum-rated cables, designed to withstand high temperatures, are often required in air ducts. Additionally, Circuit Integrity (CI) cables ensure critical systems, like fire alarms, remain functional during emergencies.

Local building codes: Local building codes impose region-specific wiring requirements, covering materials, routing, and fireproofing. Adhering to local codes ensures compliance, helps pass inspections, and protects building safety, preventing costly delays or fines.

Installation Best Practices for BMS Wiring

Proper installation of building management system wiring is crucial for ensuring efficient operation, long-term reliability, and safety. Following these best practices minimizes the risk of faults and optimizes system performance.

Pre-installation planning: Effective pre-installation planning is essential for any BMS wiring project. It involves assessing the building layout, identifying key components, and determining efficient wiring routes. Proper planning prevents obstacles, ensures zoning for systems like HVAC and security, and reduces interference between power and signal cables. It also helps estimate material needs accurately, reducing waste and ensuring the right wire types and lengths are available.

Labelling and documentation: Accurate labelling and thorough documentation simplify future maintenance. Each cable should be labelled to indicate its purpose and destination, preventing confusion during repairs. A detailed wiring diagram or map of the installation serves as a reference for technicians, ensuring consistent system upkeep.

Proper grounding: Proper grounding is vital for safety and system reliability. Grounding protects against static electricity, electrical surges, and electromagnetic interference (EMI). All BMS components must be grounded according to specifications to prevent equipment failure and communication errors.

Cable termination: Correct cable termination ensures secure connections and signal integrity. Installers must use appropriate connectors and avoid damaging conductors during termination. For communication cables like Ethernet or fibre optics, improper termination can lead to weak signals or data loss. Testing after termination ensures connections are functional.

Troubleshooting and Maintenance

BMS wiring requires ongoing troubleshooting and maintenance to ensure that the system operates efficiently over time. Knowing common issues, using the right diagnostic tools, and implementing preventive maintenance can help property managers maintain a well-functioning system.

Common Wiring Issues

Several common wiring issues can affect the performance of a BMS. Identifying and resolving these problems early is key to maintaining system reliability.

Short circuits: Short circuits occur when two conductors carrying electrical current come into unintended contact, causing excessive current flow. This can lead to equipment damage, power outages, or even fire hazards. Proper insulation and careful routing of cables can help prevent short circuits.

Signal interference: Signal interference, often caused by electromagnetic interference (EMI), can disrupt communication between BMS components. It usually occurs when power and signal wires are run too closely together, or if shielding on cables is inadequate. Separation of power and signal cables, using shielded cables, and proper grounding can mitigate these issues.

Voltage drops: Voltage drop happens when electrical power loses strength as it travels through the wiring over long distances. This can lead to underperforming equipment, especially in large buildings. The use of correctly sized wires and minimizing unnecessary cable lengths can help reduce voltage drop.

Diagnostic Tools

Using appropriate diagnostic tools is critical for quickly identifying and resolving wiring issues in a BMS.

Multimeter: A multimeter is a versatile tool used to measure voltage, current, and resistance in electrical circuits. It helps identify wiring issues like short circuits, open circuits, and voltage drops by providing immediate readings of the electrical parameters within the system. Multimeters are essential for verifying that wiring connections and components are functioning as expected.

Cable tester: A cable tester is used to check the integrity of communication cables, such as Ethernet or fibre optic lines. It verifies continuity, proper termination, and signal transmission, ensuring that data flows correctly between BMS components. Cable testers help pinpoint faults like broken connections or poor terminations that can disrupt system performance.

Preventive Maintenance

Preventive maintenance involves regularly inspecting and testing the BMS wiring to identify and address potential issues before they lead to system failures. This includes checking for signs of wear and tear on cables, verifying that terminations remain secure, and confirming that grounding systems are functioning correctly. By scheduling routine inspections and using diagnostic tools, property managers can extend the lifespan of the system, reduce the likelihood of unexpected breakdowns, and maintain efficient operations.

Preventive maintenance should also involve updating system documentation, ensuring that any changes made during repairs or upgrades are accurately reflected in the wiring diagrams. This ensures future maintenance tasks are streamlined and reduces the risk of errors due to outdated information.

Future Trends in BMS Wiring

As building management system wiring continue to evolve, so do the technologies used in wiring and connectivity. Future trends in BMS wiring aim to improve system efficiency, flexibility, and scalability. Below are some key trends that are shaping the future of BMS wiring:

Wireless BMS: Wireless BMS technology is gaining popularity as it eliminates the need for extensive wiring, reducing installation costs and complexity. Using wireless communication protocols like Zigbee, Wi-Fi, or Bluetooth, sensors and controllers can communicate without physical cables. This is particularly useful for retrofitting older buildings or managing complex layouts, providing flexibility and enabling quicker installations and upgrades.

Power over Ethernet (PoE): Power over Ethernet (PoE) combines data and power transmission over a single Ethernet cable, simplifying the wiring layout. PoE supports devices like IP cameras and access control systems, reducing the need for separate power lines and cutting installation costs. With higher-powered PoE standards, more devices can operate through Ethernet, making maintenance easier and boosting system integration.

Smart Cables: Smart cables are equipped with sensors that monitor their health, detecting faults or stress points. They improve BMS reliability by alerting managers to potential issues and providing insights into power consumption and data flow. Smart cables enhance predictive maintenance and energy management, contributing to more proactive, data-driven system management.

The Essential Steps for Wiring Building Management Security Systems

Wiring for Building Management Security Systems requires careful planning, installation, and testing to ensure that all components function seamlessly and maintain building security. Below are the essential steps involved in wiring a security system for BMS.

Planning and preparation: The first step is detailed planning. Create a wiring diagram based on the building layout and identify the locations of key components such as security cameras, access control points, and alarms. Select the appropriate cable types considering data transmission and power requirements. Planning also includes choosing routes that minimize interference and comply with local building codes.

Installing power supply and cables: Next, install the power supply in a secure, centralized location, ideally near the main control panel. During cable installation, ensure proper separation between power and data cables to prevent electromagnetic interference. Use shielded cables to maintain signal integrity and prevent tampering. Route cables through conduits or trays to keep them organized and protected.

Connecting sensors and controllers: After installing power and cables, connect sensors like motion detectors, access control readers, and cameras to their respective controllers. Follow manufacturer guidelines for wiring and secure all connections to ensure reliable communication. Test each connection before finalizing the installation.

Programming and testing the system: Finally, program the system to recognize all connected devices and thoroughly test it. Verify power supply, signal integrity, and responsiveness. Simulate potential breaches, such as unauthorized access, to ensure the system handles real-world scenarios. Document the system configuration and testing results for future reference and maintenance.

Conclusion

Understanding the wiring requirements for Building Management Systems (BMS) is crucial for ensuring optimal performance, safety, and efficiency in modern buildings. Properly planned and installed BMS wiring supports seamless communication between various systems, reduces operational inefficiencies, and minimizes risks of malfunctions or safety hazards.

From selecting the right types of cables to adhering to safety standards and regulatory codes, careful attention to wiring design and installation practices enhances the long-term reliability and functionality of a BMS. Regular maintenance and troubleshooting further ensure the system remain in peak operational condition.

Frequently Asked Questions

A BMS is a centralized platform that controls and monitors various building systems such as HVAC, lighting, security, and energy management, optimizing building performance and reducing energy waste.

Proper BMS wiring ensures reliable communication between devices, prevents operational inefficiencies, and minimizes risks like data loss, electrical hazards, or system failures.

Zoning groups building areas into manageable sections, which shortens cable lengths, simplifies troubleshooting, and enhances system performance by isolating potential issues.